Blanking is a cutting process in which a piece of sheet metal

is removed from a larger piece of stock by

applying a great enough shearing force. In

this process, the piece removed, called the blank, is not scrap but rather the desired part. Blanking can be

used to cutout parts in almost any 2D shape, but is most commonly used to cut

workpieces with simple

geometries that will be further shaped in subsequent processes. Often times

multiple sheets are blanked in a single operation. Final parts that are produced

using blanking include gears, jewelry, and watch or clock components. Blanked

parts typically require secondary finishing to smooth out burrs along the bottom

edge.

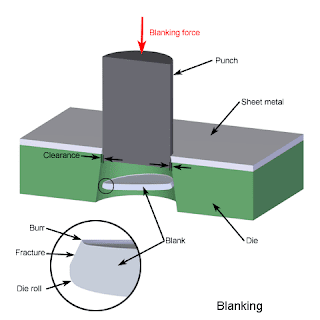

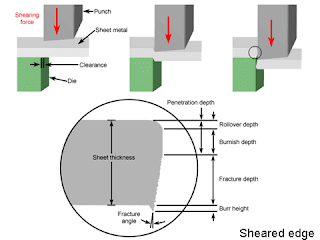

The blanking process requires a blanking press, sheet metal stock, blanking punch, and blanking die. The sheet metal stock is placed over the die in the blanking press. The die, instead of having a cavity, has a cutout in the shape of the desired part and must be custom made unless a standard shape is being formed. Above the sheet, resides the blanking punch which is a tool in the shape of the desired part. Both the die and punch are typically made from tool steel or carbide. The hydraulic press drives the punch downward at high speed into the sheet. A small clearance, typically 10-20% of the material thickness, exists between the punch and die. When the punch impacts the sheet, the metal in this clearance quickly bends and then fractures. The blank which has been sheared from the stock now falls freely into the gap in the die. This process is extremely fast, with some blanking presses capable of performing over 1000 strokes per minute.

The blanking process requires a blanking press, sheet metal stock, blanking punch, and blanking die. The sheet metal stock is placed over the die in the blanking press. The die, instead of having a cavity, has a cutout in the shape of the desired part and must be custom made unless a standard shape is being formed. Above the sheet, resides the blanking punch which is a tool in the shape of the desired part. Both the die and punch are typically made from tool steel or carbide. The hydraulic press drives the punch downward at high speed into the sheet. A small clearance, typically 10-20% of the material thickness, exists between the punch and die. When the punch impacts the sheet, the metal in this clearance quickly bends and then fractures. The blank which has been sheared from the stock now falls freely into the gap in the die. This process is extremely fast, with some blanking presses capable of performing over 1000 strokes per minute.

Fine blanking is a specialized type of blanking in which the blank is sheared

from the sheet stock by applying 3 separate forces. This technique produces a

part with better flatness, a smoother edge with minimal burrs, and tolerances as

tight as ±0.0003. As a result, high quality parts can be blanked that do not

require any secondary operations. However, the additional equipment and tooling

does add to the initial cost and makes fine blanking better suited to high

volume production. Parts made with fine blanking include automotive parts,

electronic components, cutlery, and power tools.

Most of the equipment and setup for fine blanking is similar to conventional blanking. The sheet stock is still placed over a blanking die inside a hydraulic press and a blanking punch will impact the sheet to remove the blank. As mentioned above, this is done by the application of 3 forces. The first is a downward holding force applied to the top of the sheet. A clamping system holds a guide plate tightly against the sheet and is held in place with an impingement ring, sometimes called a stinger, that surrounds the perimeter of the blanking location. The second force is applied underneath the sheet, directly opposite the punch, by a "cushion". This cushion provides a counterforce during the blanking process and later ejects the blank. These two forces reduce bending of the sheet and improve the flatness of the blank. The final force is provided by the blanking punch impacting the sheet and shearing the blank into the die opening. In fine blanking, the clearance between the punch and the die is smaller, around 0.001 inches, and the blanking is performed at slower speeds. As a result, instead of the material fracturing to free the blank, the blank flows and is extruded from the sheet, providing a smoother edge.

Most of the equipment and setup for fine blanking is similar to conventional blanking. The sheet stock is still placed over a blanking die inside a hydraulic press and a blanking punch will impact the sheet to remove the blank. As mentioned above, this is done by the application of 3 forces. The first is a downward holding force applied to the top of the sheet. A clamping system holds a guide plate tightly against the sheet and is held in place with an impingement ring, sometimes called a stinger, that surrounds the perimeter of the blanking location. The second force is applied underneath the sheet, directly opposite the punch, by a "cushion". This cushion provides a counterforce during the blanking process and later ejects the blank. These two forces reduce bending of the sheet and improve the flatness of the blank. The final force is provided by the blanking punch impacting the sheet and shearing the blank into the die opening. In fine blanking, the clearance between the punch and the die is smaller, around 0.001 inches, and the blanking is performed at slower speeds. As a result, instead of the material fracturing to free the blank, the blank flows and is extruded from the sheet, providing a smoother edge.

As a professional stamping parts manufacturer and metal parts fabricator,we have advanced equipments and machines, serious quality control, fast leading time and competitive price.Email us for more information:

rainbowrt@ymail.com

Mobile:0086-13260091203

Skype:abramdong

rainbowrt@ymail.com

Mobile:0086-13260091203

Skype:abramdong